By Anthony M. Wanjohi: Determination of the size of biogas plant is a critical issue in biogas installation process. Another sphere of interest is the question of the amount of biogas produced. This article provides the calculations of the size of biogas plant (digester and gas holder), and calculations of the amount of biogas produced by the plant.

1. Introduction

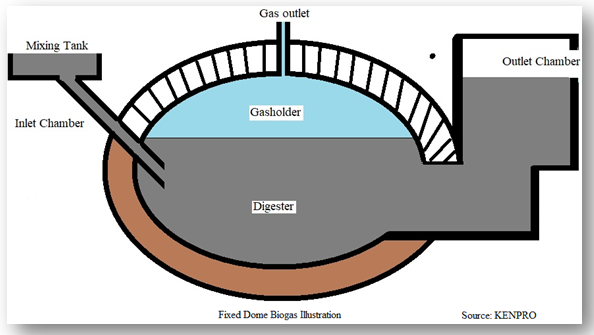

For the purpose of determining the biogas plant size and the amount of biogas produced, the following background details of a case Household Fixed Dome Biogas Plant are outlined:

- A household with 3 cows (zero grazing),

- 10 kg of dung per cow in a day (from literature)

- Total solid (TS) is estimated at 20%,

- Volatile Solid (VS) estimated at 80% of TS,

- Cattle manure biogas yield/Kg: 0.35 (from literature)

- Optimum mixing ratio, dung: water (1:3) (1:1 ratio may also be used – Literature)

2. Biogas Plant Size Determination

2.1 Digester Size Calculations

Amount of waste per day: In order tom determine the size of the digester, we need to assess the amount of waste per day. Thus, based on background details pro:

3 Cows ∗10 Kg/Day = 30 Kg/Day

The animal waste is mixed with water using dung to water ratio of 1:3

Thus, 1*30 + 3*30 = 120 Litres

Hydraulic Retention Time (HRT): The ideal HRT for a tropical climate with an average ambient temperature of 25–30°C is recommended to be around 30 days.

Thus, reaction time = 30 days

Thus, digester size: To obtain the size of the bio digester, we multiply the amount of feedstock per day and Hydraulic Retention Time:

120 L/ Day ∗ 30 Days = 3600 = 3.6M3

2.2 Gas holder Size Calculations

Based on literature, the size of a digester is 75% while the gas holder is 25%. Thus, gasholder size is calculated as follows:

If 75% = 3.6 M3; 25% = 1.2 M3

2.3 Total Biogas Plant Size

The total volume of the biogas plant is:

Digester Size + Gasholder Size

3.6M3 + 1.2 M3 = 4.8 M3

3. Amount of Biogas Calculations

In order to determine the amount of gas, we compute the feedstock quality using Total Solids, Volatile Solids and Organic Loading Rate (OLR) as follows:

3.1 Feedstock Quality

Total Solid is (TS) content is 20%.

Thus, Total Solid (TS) for 30 Kgs is: 30 Kg ∗ 20% = 6 Kgs

Volatile Solids (VS) content on the other hand is estimated at 80% of TS (dry matter).

Thus, Volatile Solids (VS) = 80% ∗ 6 Kg = 4.8 Kgs VS/Day.

To arrive at the concentration / quality of the feedstock in cubic meters, we compute:

VS / daily feedstock *1000

4.8 /120 ∗1000 = 40Kgs VS/ M3

3.2 Organic Loading Rate (OLR)

Organic loading rate (OLR) in biogas refers to the rate at which organic matter is added to an anaerobic digestion system

Organic Loading Rate (OLR) = Flow Rate ∗ Feedstock Concentration / Digester Volume

Flow Rate = 120/1000 = 0.12 M3/ Day

Thus, 0.12 M3 ∗ 40 Kgs VS/ M3 / 3.6 M3 = 1.33 Kgs VS/ M3

Note: From literature, OLR below 2 kg is appropriate.

3.3 Biogas Amount

Amount of biogas = Organic Loading Rate (OLR) * Biogas Yield from cow dung * Digester Volume.

Thus: 1.33 Kgs VS/ M3 ∗ 0.35 ∗ 3.6 M3 =1.7 M3/Day

Note: The biogas yield for cow dung is computed based on the one cow dung-production in a day, which is 10Kg. From literature, 1 kg of cow dung produces about 0.035 M3 (35 liters of biogas). Thus, gas yield for one cow per day is about 0.35 M3(350 liters).

Number of cooking hours in 1 burner stove

Estimating the average consumption of a biogas stove to be 0.4 M3/hour, the plant therefore provides 4 hours of cooking for 1 burner stove.

4. Conclusion

In the construction of a biogas plant, calculating the estimates of plant size and the amount of biogas amount is an important step in biogas plant project planning and implementation phases. Without these estimates, it is hard to make other estimations including financial and application of the biogas.

About the Author

Wanjohi is an author, a scholar, an educationist, a social research scientist, a development expert in the field of sustainable development and an innovator. He is the founder and Director of Projects and Research at KENPRO and Editor in-chief of the African Research Journal of Education and Social Sciences (ARJESS). In the last 2 decades, Wanjohi has reviewed and edited over 1,000 scholarly and scientific works in the context of Sub-Saharan Africa. Author E-mail: wanjohi@kenpro.org | Website: http://www.kenpro.org/

Further Reading Resources

Vögeli Y., Lohri C. R., Gallardo A., Diener S. and Zurbrügg C. (2014). Anaerobic Digestion of Biowaste in Developing Countries: Practical Information and Case Studies. Swiss Federal Institute of Aquatic Science and Technology (Eawag), Dübendorf, Switzerland.

Wanjohi, A.M. (2022). The Blue Flame: Biogas Training Blueprint. Nairobi: KENPRO Publications.

Kenpro Biogas Program covers both portable domestic biogas and fixed dome biogas plants installations. For inquiries about Biogas installation at institutional and household levels, kindly contact Kenpro Biogas Program Team or call us +254725788400.

Interested to learn how to construct biogass plant