By Anthony M. Wanjohi: Anchored on Sustainable Development Goal 7, biogas as a source of clean and sustainable cooking energy is a perfect way to contribute to sustainable development goals. However, owing to various challenges facing the biogas especially in developing economies, including cost implications and policy gaps, there is a need to think of affordable biogas solutions tied around the concept of a portable biogas plants in order to meet the energy gaps of the rural and peri-urban areas and to counter the effects of climate change. This article provides an overview of three designs of Portable Domestic Household Biogas Plants in developing economies perspective. These include Balloon Biogas Plant, Plastic Biogas plant and Polyethylene Tube Digester.

An Overview of Portable Biogas Plants

1. Balloon Biogas Plant

Portable domestic household biogas plants are of various types. One common type in Kenya bears a membrane digester and a gas storage bag combined in one. The digester is made of special material with characteristics of anti-aging, acid, and alkali resistant and ultraviolent proof.

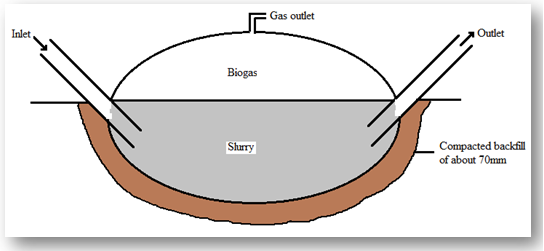

As illustrated, balloon plant is constituted of a heat-sealed plastic also called a rubber bag (balloon), a gas holder and digester. The upper part of the balloon stores the gas while both the inlet and the outlet are attached directly to the skin of the rubber bag. To increase gas pressure, weights can placed on the rubber bag but if the gas pressure goes beyond the limit that the balloon can hold, it could damage the skin. Safety valves are therefore installed. When high pressure is required from the gas, a gas pump is used. To counter weather and UV effects, a resistant material to the conditions is used preferably plastic or synthetic material. A balloon plant has a useful life-span of 2-5 years.

Advantages of the balloon plant design

- Can be transported easily

- Low maintenance and ease in emptying

- Construction is not sophisticated

- It can be easily cleaned

Disadvantages of the balloon plant

- Gas pump needed due to low pressure

- During operation it is not easy to remove scum

2. Portable Plastic Biogas Plant

Among the many designs of portable biogas plants available in the market, India stands out in Plastic Biogas plant designs. The most common material used to make the plastic plant is Fiber Reinforced Plastic (FRP).

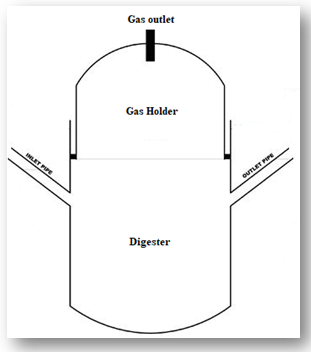

A portable Plastic Biogas Plant is illustrated as shown. Slurry is fed through the inlet into the digester,above the digester is a gas chamber. Exess slurry leaves the system through the outlet.The system is designed in such away that biomenthenization takes place converting food waste to liquid manure and methane.

A design of 1m3, can produce between 250 to 400 liters of methane per day when using cow dung as the feedstock. Note that different feedstocks have varied biogas yield.

3. Polyethylene Tube Digester

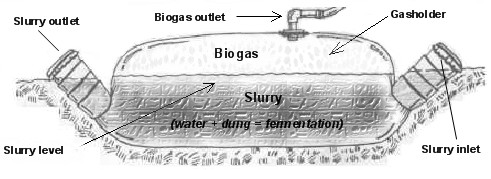

The Low-Cost Polyethylene Tube Digester is home biogas model that is already in use in South America i.e. Bolivia and other countries such as Peru and Mexico. Two coats of 300 microns: referred to as tubular polyethylene film is bended on both ends around a PVC drainpipe of 6 inch and recycled rubber strap is used to wound. A hermetic isolated tank is therefore obtained from the system.

How the system works

- Slurry is let into and out of the system through the 6 inch PVC drainpipes.

- When slurry gets into the tube, a hydraulic level is set that allows as much quantity of prime matter to get inside as an equal quantity of fertilizer leave the system through the outlet

- It is important to construct a “cradle” that holds the reaction tank, therefore a trench is excavated

Portable Biogas Plant Design Specifications Highlights

The following comprises of the portable biogas plant design specifications of a typical plant:

| Plant Size/ Capacity | 1M3 (1000 liters) |

| Area occupied | 10.76 ft2 |

| Feedstock/per day | 20 Liters (optimum results – cow dung:water 1:3) |

| Gas produced per day | About 250 to 400 liters with cow dung |

| Calorific Energy | 6kWh (via generator is reduced to 2kWh of electric energy) |

| Cooking hours | 2-3 hrs of cooking using a single burner stove |

| Plant design | Standard/ Utility Model |

Why Portable Biogas Plants?

Affordability

The portable biogas plant is made from relatively cheap materials. This reduces the production cost, thus drastically reducing the installation costs and therefore making it affordable to consumers in rural and peri-urban areas in developing economies.

Portability

The biogas plant is light and can be moved to any convenient location as long as it is close to the kitchen area.

Ease of Installation

It is simple to set up the portable biogas system as the system is made up of parts that can be attached. A manual that comes with every product provides simple instructions that the user can follow to install the system in minutes.

Recycle-ability

Domestic Portable Biogas Plant is made of recyclable materials. For instance, when PVC is recycled, the carbon footprint is drastically reduced as compared to the production with fresh materials.

Conclusion

The three illustrated portable household biogas plants are just but a few among many designs that are available in the marketplace today. The designs of the plants may slightly vary from one make to another. The essense of the highlighed designs was to provide a general overview in order to inform the reader about general operations of the portable biogas plants which are low costs in terms of installation as compared to fixed dome biogas plants designs.

About the Author

Wanjohi is an author, a scholar, an educationist, a social research scientist, a development expert in the field of sustainable development and an innovator. He is the founder and Director of Projects and Research at KENPRO and Editor in-chief of the African Research Journal of Education and Social Sciences (ARJESS). In the last 2 decades, Wanjohi has reviewed and edited over 1,000 scholarly and scientific works in the context of Sub-Saharan Africa. Author E-mail: wanjohi@kenpro.org | Website: http://www.kenpro.org/

Further Reading Resources

Artanti, R.D., Saputro, R. & Budiyono, B. (2012). The effect of water addition ratio in biogas production. Available at: https://www.researchgate.net/figure/The-effect-of-water-addition-ratio-in-biogas-production_fig2_235943053

Energypedia (2015). Balloon digester for biogas plants. Available at: https://energypedia.info/wiki/Balloon_Digester_for_Biogas_Plants

Energypedia (n.d). Sizing of the Biogas Plant. Available at: https://energypedia.info/wiki/Sizing_of_the_Biogas_Plant

Gazpack (n.d). Manure digestion for biogas from cow/pig/chicken. Available at: https://gazpack.nl/en/biogas-from-cow-dung-pig-and-chicken-manure/

Khan, et al (2017). Production of biogas by the co-digestion of cow dung and crop residue at University of the Punjab, Lahore, Pakistan. Retrieved from https://academicjournals.org/journal/AJEST/article-full-text-pdf/2E47A6C55601

Margo (2022). What is a biogas plant and how does it work?, HomeBiogas. Available at: https://www.homebiogas.com/blog/what-is-a-biogas-plant-and-how-does-it-work/

Vögeli Y., Lohri C. R., Gallardo A., Diener S. and Zurbrügg C. (2014). Anaerobic Digestion of Biowaste in Developing Countries: Practical Information and Case Studies. Swiss Federal Institute of Aquatic Science and Technology (Eawag), Dübendorf, Switzerland.

Wanjohi, A.M. (2022). The Blue Flame: Biogas Training Blueprint. Nairobi: KENPRO Publications.

Kenpro Biogas Program covers both portable domestic biogas and fixed dome biogas plants installations. For inquiries about Biogas installation at institutional and household levels, kindly contact Kenpro Biogas Program Team or call us +254725788400.