By Anthony M. Wanjohi

Interlocking Brick Making Technology has the potential of sealing the housing gaps in developing economies like Kenya. Interlocking soil bricks allow for the quick and cost efficient construction of housing units and other buildings. As per 2015 estimations, Kenya has a deficit of 2.5 million units that continues to grow at a rate of over 200,000 units per year. Interlocking brick making machines, which could help to address the gap, are already in the market place. For instance, Hydraforms Interlocking and Conventional Brick making machines are currently being used across Africa by property developers, entrepreneurs, governments and NGOs.

Fig.1: Hydraform Brick Making Machine

The technology behind any Brick Making Machine involves production of earth and clay bricks, with addition of water and cement. Mathematically, this translates into the following simple equation: Earth + Water + Cement (optional) = Interlocking Earth Brick.

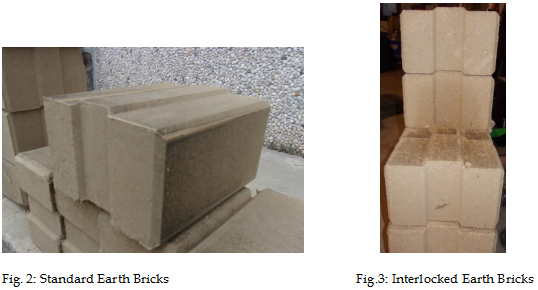

There are different types of bricks that are produced using the Brick Making Machines depending on the mould. The most common types of bricks that are produced include standard soil brick which bear the following measurements: width 20cm, length 24cm, height 12.5 cm. Figures 2 and 3 show sample interlocking earth bricks.

While interlocking bricks are slowly finding their place in Kenya’s market, there are a number of questions that continue to be raised: what is the durability of soil bricks as compared to the conventional blocks? Can earth bricks withstand adverse whether conditions such as rain and fog? what is the best soil to prepare these bricks? Are there existing standards to guide earth brick production? These and many other questions continue to linger mainly on the minds of consumers. Thus, in as much as earth bricks technology has potential of providing a quick answer to the housing problem in Kenya, there is need for standardization of all forms of earth and clay products including flooring and roofing materials.